Grolleau Industrial site

Our company covers a total area of 60,000 m² in the heart of Anjou, 18,000 m² of which is used by:

- the head office and its Human Resources, Sales & Sales Administration, QSE (Quality, Safety & Environment), Finance, and Logistics departments

- the technical centre with its R&D, Design, Industrialisation, Testing & Qualification, and After-Sales Service departments

- the production site consisting of sheet metal workshops, an automated painting line, as well as an assembly & integration-testing workshop

- ISO9001 and EN15085 certified site.

Production means

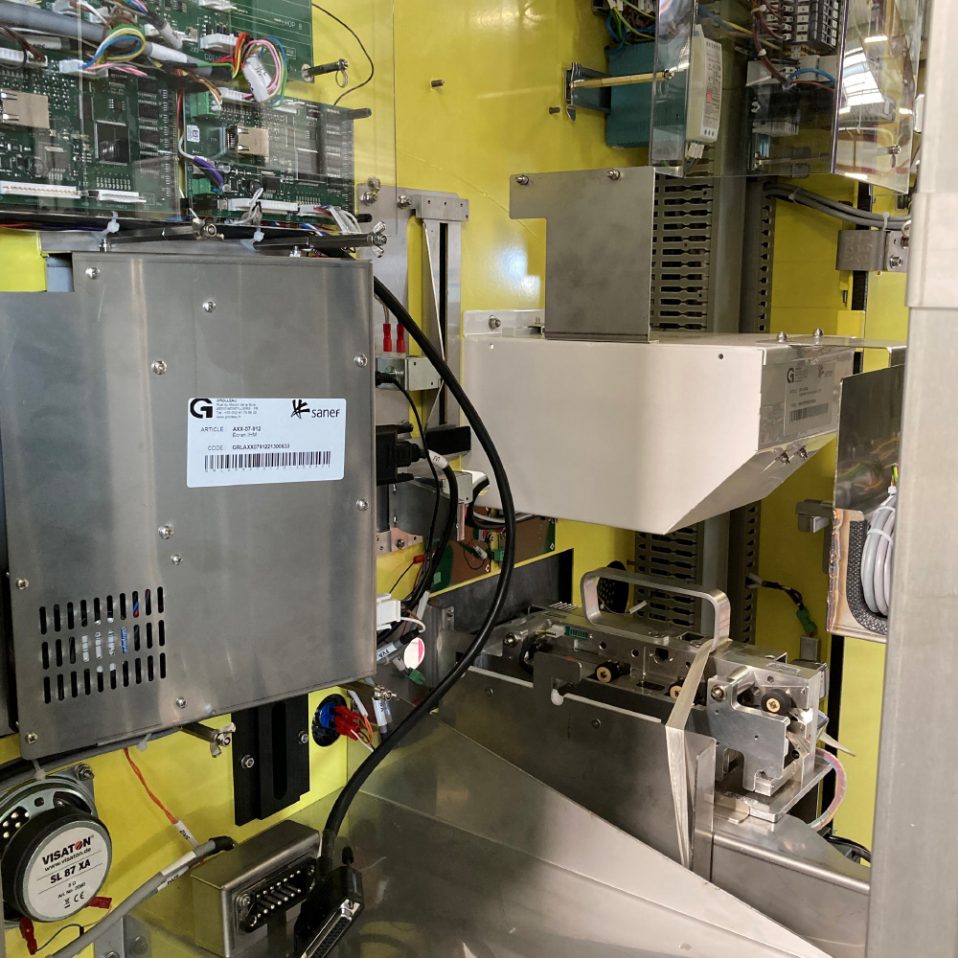

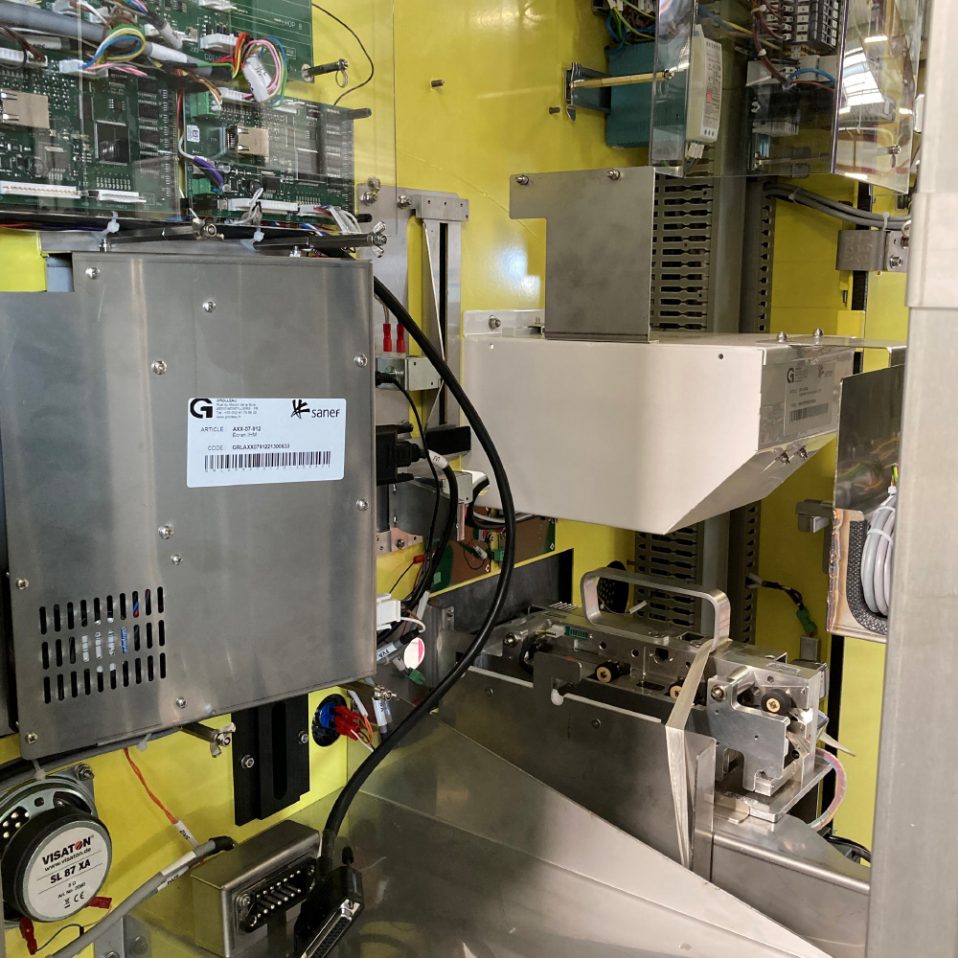

The production line is perfectly adapted to sheet metal transformation, but above all to the integration of your sensitive components within the created and manufactured enclosures.

0 1

Thanks to its on-site integrated production means, GROLLEAU provides you with efficient product manufacturing as well as total, partial, or bespoke integration of your equipment and finished products.

0 2

An EMC zone is reserved to integrate your sensitive circuits. At the end of the line, we perform electrical and functional tests.

0 3

Production site

Grolleau’s production site consists of two juxtaposed buildings:

- a 7000m² Sheet Metal & Welding Unit (aluminium, stainless steel, steel…),

- a 1000m² Painting Unit,

- a 10,000m² Assembly, Integration & Testing Unit.

The production team, supported by the Methods Department, is able to respond in real-time to customer orders and product configuration changes.

Thanks to its integrated BAAN Management system and the close collaboration of the Sales Administration Department, GROLLEAU ensures a 98% delivery rate and delivers to 15 different customers every day.